O Ring Selection

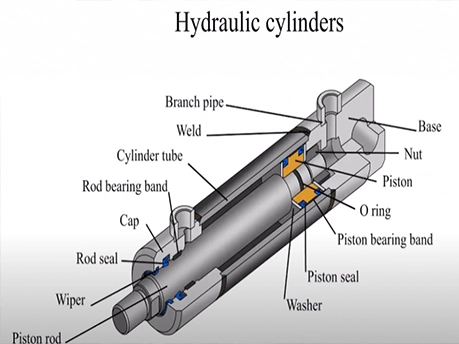

Selecting the right O-ring involves considering several critical factors to ensure optimal performance and longevity. First, the material must be chosen based on the application’s environmental conditions, such as temperature, pressure, and exposure to chemicals. Common materials include nitrile rubber (NBR) for general purposes, fluorocarbon (Viton) for high-temperature and chemical resistance, and silicone for extreme temperature ranges. The size of the O-ring, including its inner diameter and cross-sectional thickness, must match the groove dimensions precisely to ensure a proper seal. Additionally, the hardness of the O-ring, measured in durometers, should be appropriate for the pressure and mechanical stress it will encounter. Compatibility with the fluid being sealed is also crucial to prevent degradation. Proper selection ensures reliability, reduces maintenance, and enhances the efficiency of the hydraulic system.

English

English Indonesia

Indonesia