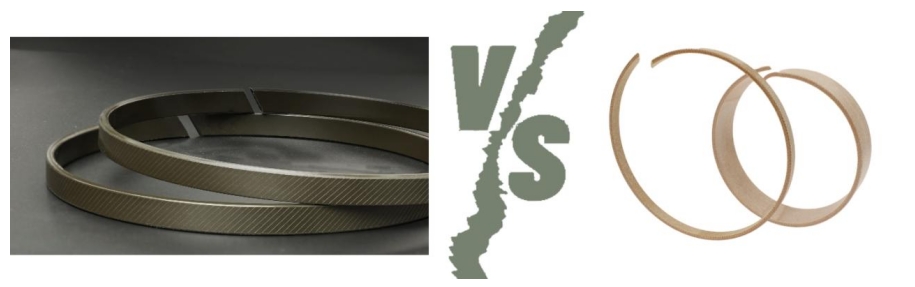

Professional comparison between TPI wear rings and phenolic fabric guide rings for excavator hydraulic cylinders. Discover critical differences in friction, temperature resistance, and TCO.

Wear rings (Guide rings) are critical components for:

Axial force transmission (30-50MPa dynamic pressure)

Piston rod guidance (precision <0.1mm)

Friction pair protection (reducing seal wear)

Material choice impacts:

Annual downtime (+45-60 hours with inferior materials)

Hydraulic oil contamination (3x higher particle count)

Total Cost of Ownership (TCO) ($12,000 difference over 5 years)

Thermoplastic Polyimide (TPI) wear rings certified to ISO 6070 deliver:

Ultra-low friction: 0.08-0.12 dynamic coefficient (40% reduction)

Extreme temperature stability: -50℃ to 260℃ with >90% strength

Lubrication-free operation: 5GPa modulus cuts installation time by 50%

Chemical inertness: Compatible with PH 2-12 hydraulic fluids

Industry applications: Caterpillar mining excavators, Liebherr polar equipment

Phenolic fabric guide rings face critical challenges:

Thermal degradation: 18% load capacity loss per 10℃ above 80℃

Moisture expansion: >0.12mm dimensional change at >60% humidity

Dynamic fatigue: Crack initiation after 2 million cycles

Cost reality: 40% lower upfront cost, but higher TCO beyond 2 years

Metric | TPI Wear Rings | Phenolic Guide Rings |

Temperature Range | -50℃~260℃ | -30℃~120℃ |

Dynamic Friction | 0.08-0.12 | 0.18-0.28 |

Compression Retention | 93%@3000hrs | 72%@1500hrs |

Chemical Resistance | PH 2-12 | PH 5-9 |

Load type: High-frequency impacts → Mandatory TPI

Environment: >100℃ delta or corrosive media → TPI recommended

Cost model: Service life >3 years → TPI saves TCO

Case Study: XCMG XE3700 Excavator Retrofit

After switching to TPI wear rings:

Cylinder overhaul interval extended from 2500 to 4000 hours

Hydraulic cleanliness improved by 2 NAS grades