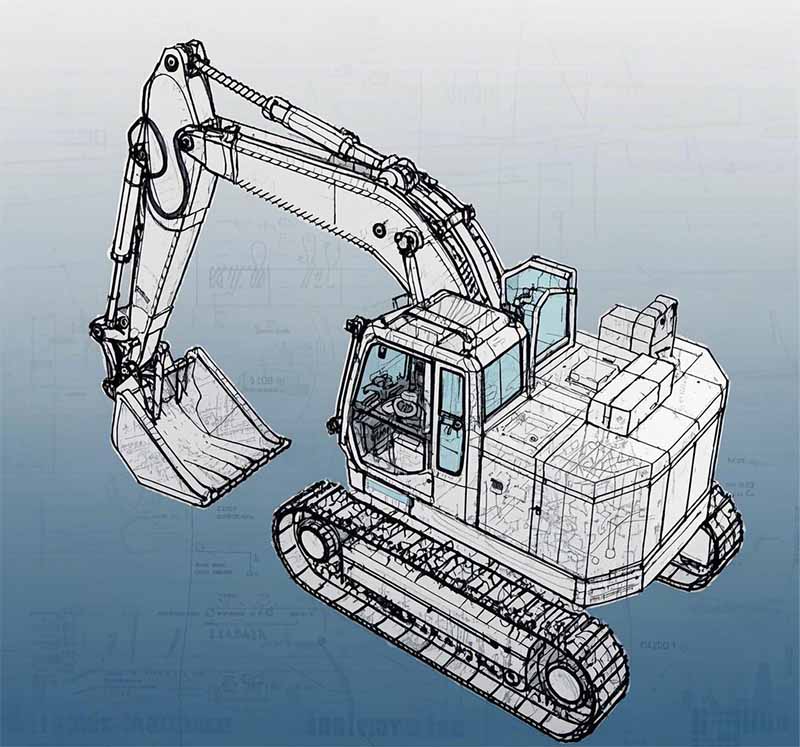

In excavator operation, the front work attachment plays a key role, with the bucket being the primary working component. For the bucket to function effectively, the hydraulic cylinders in the boom, arm, and bucket must work in harmony, performing a variety of complex movements. One common issue that arises is hydraulic pressure loss, which manifests as the boom dropping, the arm lowering, or the bucket automatically losing its grip. This article explores the hydraulic system principles and common issues that lead to these problems, providing insights into diagnosis and repair.

The hydraulic oil flows from the main pump to the control valve, passing through components like the safety valve and holding valve before entering the hydraulic cylinders. The oil is then directed into the cylinders to perform the required actions.

On the other side of the cylinder, the hydraulic oil flows through the control valve and returns to the oil tank via the cooler for cooling and filtration before being recirculated.

The safety relief valve (also known as the pipeline safety valve) in the excavator hydraulic system serves as a protective measure. When the hydraulic pressure exceeds a preset limit, the valve opens to release excess pressure by diverting part of the hydraulic oil back into the return line, preventing accidents caused by overpressure.

The holding valve is typically installed between the boom cylinder and the boom control valve. For example, when the boom cylinder is in a neutral (non-moving) position, the holding valve maintains hydraulic pressure to prevent the boom from lowering due to its own weight. This valve acts like a hydraulic lock, ensuring stability. As the flow rate through the valve is high during normal operation, an insert valve structure is commonly used.

One-way valves, often referred to as safety compensation valves, are used in the boom circuit to prevent abnormal high pressure or vacuum caused by inertia when hydraulic actuators move.

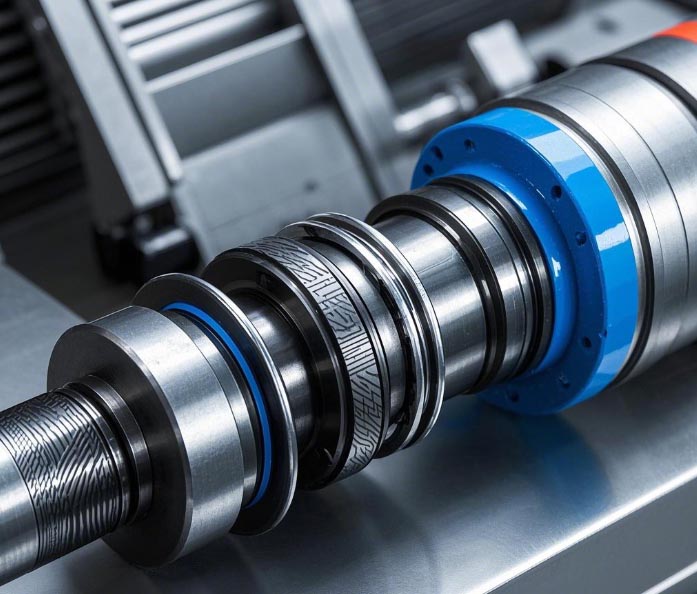

Excavator cylinders are designed to have a strict seal between the rod chamber and the piston chamber. The seals prevent hydraulic oil from mixing between these two chambers. However, after prolonged use under high pressure and temperature, seals may wear, deform, or degrade, leading to internal leakage. This internal leakage results in a loss of pressure and can cause components like the boom, arm, or bucket to move unexpectedly.

Hydraulic valves such as the holding valve, relief valve, one-way valve, and safety valve undergo frequent movement during operation. Over time, these valves can wear, causing internal leakage. This leakage is a common cause of the boom or arm dropping during operation. To mitigate the risk of cylinder sinking and improve work efficiency, most manufacturers install locking valves in the control valves.

When cylinder seals or safety valves fail, the system may experience increased leakage, resulting in excessive dropping of components. For instance, if the arm cylinder seals are damaged, the arm may lower significantly when extended, while the retracted state remains relatively stable. In such cases, do not attempt to disassemble the arm cylinder immediately. If you notice that the arm is dropping faster when retracted than when extended, swapping the safety valves between the rod and piston chambers can help pinpoint the faulty component.

If replacing or swapping safety valves does not resolve the issue, check the return oil filter for rubber fragments or metal shavings. If rubber fragments are found, this often indicates that the cylinder seals are severely worn and need replacing. After replacing the seals, if the boom or arm still drops, you may need to inspect the holding valve.

1. After replacing the cylinder seals, check the holding valve for wear. If necessary, disassemble and repair or replace the valve.

2. If the issue persists even after repairing the holding valve, the next step is to examine the main control valve. This involves checking all the valve spools in the hydraulic circuit to ensure they are functioning correctly. Replace or repair any damaged valves.

1. After repairing or replacing faulty valves, if the dropping issue persists, disassemble the main control valve and inspect all its internal components, including the valve spools and seals. It may be necessary to replace damaged components to fully restore normal operation.

The problem of boom dropping in excavators is often linked to issues in the hydraulic system, such as worn seals, internal leakage in valves, or inadequate pressure maintenance. Diagnosing the root cause and addressing it with the correct parts—whether it's replacing cylinder seals, repairing valves, or ensuring proper pressure regulation—can restore the excavator’s functionality.

As a hydraulic oil seal exporter and leading manufacturer of hydraulic seals and sealing components, we understand the critical importance of high-quality, durable seals for excavators and other machinery. Our products help ensure the long-term performance of your hydraulic systems, preventing downtime and costly repairs. If you're experiencing issues like boom dropping, consider inspecting the hydraulic components and seeking expert solutions for replacement parts.