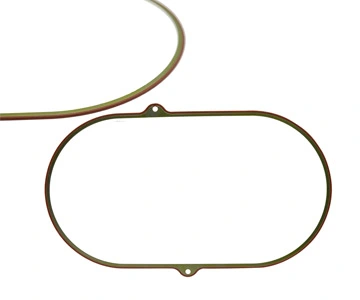

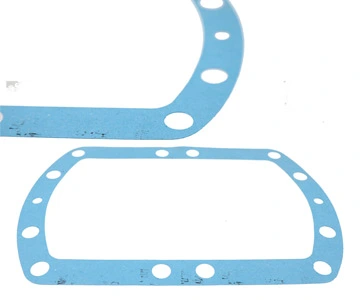

Gasket Seals Role

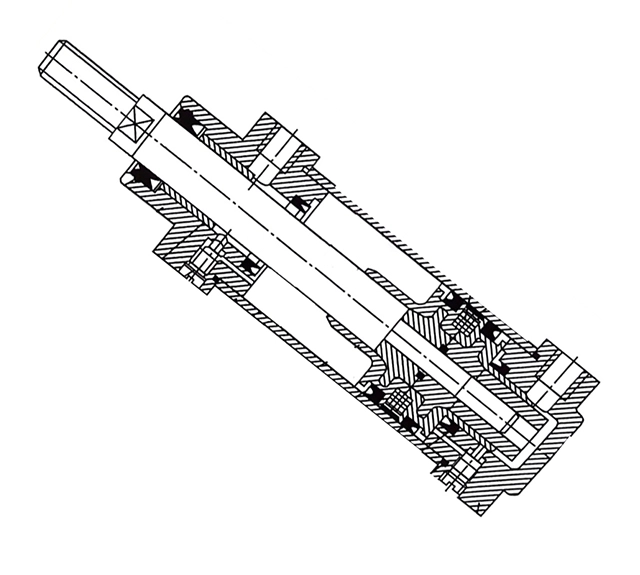

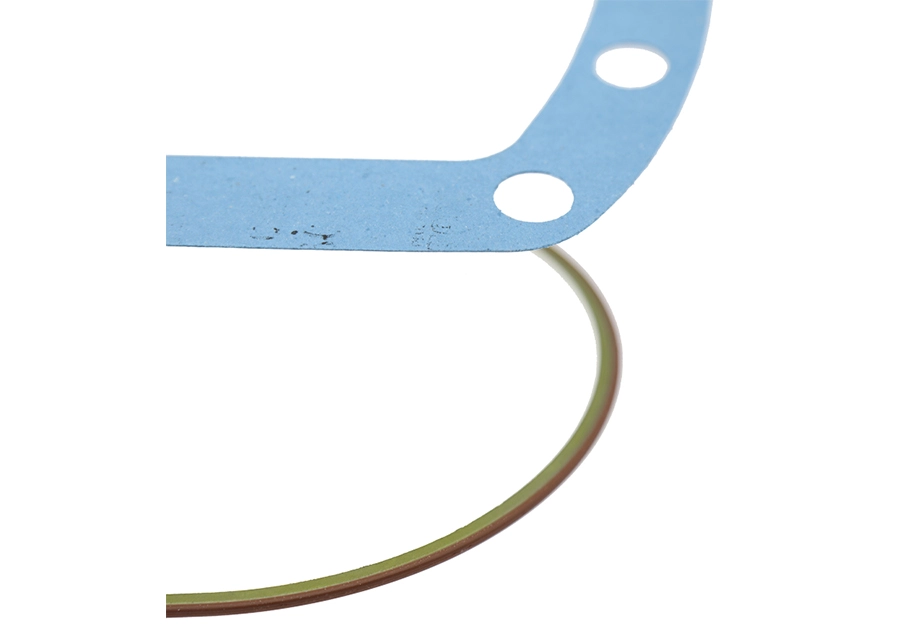

Gasket seals play a crucial role in various mechanical and industrial applications by providing a reliable seal between two mating surfaces. Their primary function is to prevent the leakage of fluids (liquids or gases) and to maintain pressure within a system. Here are some key roles of gasket seals:

Leak Prevention: Gasket seals fill the microscopic gaps and irregularities between mating surfaces, ensuring that no fluids escape from the system. This is essential in applications like engines, pipelines, and pumps.

Pressure Maintenance: By creating a tight seal, gaskets help maintain the required pressure within a system, which is vital for the efficient operation of hydraulic and pneumatic systems.

Vibration Dampening: Gaskets can absorb vibrations and shocks, reducing the risk of damage to the components they are sealing. This is particularly important in automotive and heavy machinery applications.

Chemical Resistance: Gaskets are often made from materials that can withstand exposure to various chemicals, ensuring long-term durability and performance in harsh environments.

Thermal Insulation: In high-temperature applications, gaskets can provide thermal insulation, protecting sensitive components from heat damage.

Electrical Insulation: Some gaskets also offer electrical insulation properties, preventing electrical currents from passing between components.

Overall, gasket seals are essential for ensuring the integrity, efficiency, and safety of mechanical systems across a wide range of industries.

English

English Indonesia

Indonesia