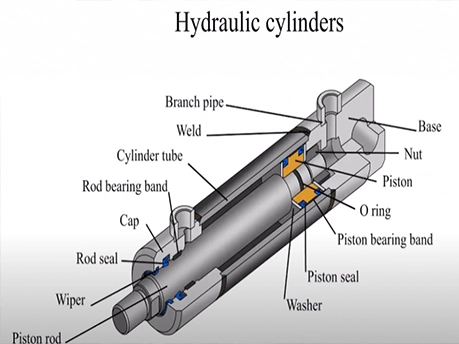

Role of Buffer Seals

Buffer seals play a crucial role in the hydraulic systems of excavators, particularly in the hydraulic cylinders that control the movement of the boom, arm, and bucket. These seals are designed to absorb shock and reduce pressure spikes within the hydraulic system, thereby protecting other seals and components from damage.

When an excavator operates, it often encounters varying loads and impacts, especially during digging and lifting activities. Buffer seals are positioned in front of the primary rod seals to absorb these shocks and pressure surges. By doing so, they help to prevent hydraulic fluid leakage and reduce wear and tear on the primary seals. This not only extends the lifespan of the hydraulic cylinders but also ensures smoother and more efficient operation.

Additionally, buffer seals help to maintain the integrity of the hydraulic system by preventing contaminants from entering and causing damage. They act as a secondary line of defense, ensuring that the hydraulic fluid remains clean and the system operates at optimal performance.

In summary, buffer seals are essential for enhancing the durability, efficiency, and reliability of an excavator’s hydraulic system, ultimately contributing to the machine’s overall performance and longevity.

English

English Indonesia

Indonesia